Original Posted:: Sun Mar 20, 2016 3:46 pm

MC2 Torsen Kit Install

http://forum.merkurclub.com/forum/viewt ... 30&t=32493

Original Posted:: Mon Apr 18, 2016 8:14 pm

*/

Took all that time rereading the rear axle procedure and differential install I overlooked something that set me back two days, jack points. Installed a MC2 diff mount while I was here only to have the mount be 1/4" behind the holes on the body. I had put the stands on the crossmember, which caused the suspension to flex to the point where nothing would line up. Thanks to Grayson, yet again, for helping me on this oversight.

/*

Took it for a quick drive to feel out the driveshaft and feel for anything noticeable, all seemed fine. Has excellent traction where it use to struggle for grip, very predictable feel throttling through corners. Suspension is still 'floaty' feeling and lacking tire grip.

Now onto the turbo. If you've been reading, there have been noticeable things around or about the turbo since I got the car.

1) Brown oil film lined the inside of the manifold all the way to the compressor.

2) Compressor wheel has some sheared edging.

3) The 'misfire' issue went away after deleting the coolant lines to the turbo.

------------------------------------

Turbo Wheel Condition Information

Wasn't too sure on the compessor condition. Read a few write ups online and even a few books on turbos, nothing really describes wheel condition like the spark plug condition charts. Few people in my area that have worked on them before didn't really give me a straight answer either. I ended up buying a replacement, however light fin damage can be lathed off and salvaged much like brake rotors/drums.

-------------------------------------

Since the compressor is being addressed, a balancing will be needed. Even if it isn't necessary, completely rebuilding with upgraded 360 thrust bearing. G-Pop is an excellent store that even sends instructions on general assembly process.

*/

Most everything you see on here is self taught, book reading and/or internet research/help and I'm doing it first time here. All the knowledge doesn't matter if you don't have the experience to back it up, or the initiative to try without it.

/*

Stripped turbo down and inspected. Couldn't afford a $200+ 3-point ID micrometer, got it measured at turbo shop.

http://www.d-series.org/forums/diy-foru ... tures.html

Taking the turbine housing off took more then "lightly tap" procedure with heat. Make sure you have an oxy-acytelyne torch when you do this, most likely it's the first time it's been apart since it left the factory. Not sure how you get this in a vice. Pinching the turbo between two tables is much easier. Had to heat the joint area to the point where it was probably as hot running on the car, bracket edges glew to the brink of melting it seemed. Barely handle the thing even with gloves. With a rubber hammer, whaled on an edge a couple of blows and checked the turbine for rubbing on the housing to reposition my blows, with repeat of torching. Will assemble with anti-seize film on this lip for easier future removal.

Shaft OD Exh 0.3998

Bearing ID Exh 0.4008 =0.0009" Clearance

Shaft OD Int 0.3998

Bearing ID Int 0.4001 =0.0012"

Housing ID Exh 0.6220

Bearing OD Exh 0.6184 =0.0016"

Housing ID Int 0.6220

Bearing OD Int 0.6185 =0.0015"

Everything is within spec and is visibly good so I could have gotten by on just a $20 balancing, wheel edge cleaning, and basic gasket kit. The shaft-bearing clearance has a 0.0015" service limt, so some possible concern on Int side.

Assembly is really simple, hardest thing is setting the compression oil seal ring and bolt torques. Loosely installed compressor housing on. Turbine housing bolts line up with water taps, however the turbine mounting surface is at a right angle with the oil feed line surface. I use the OEM actuator so a mock up of the attachment on the compressor housing was necessary for fit. After installing back on the car, I started the engine without running to get the oil to the turbo before a proper start.

On a side note, got replacement front fender flares that didn't come on car. Can't install due to fenders being rolled by a previous owner.

Original Posted:: Fri Apr 29, 2016 9:42 pm

Car was spitting 3+ quarts after some full boost sprints. Wish the oil light would have worked, not sure how bad the bearings got in the engine and the turbo are now. From people with more experience than me, the PCV valve needed to be replaced. Rather then replace it, I just spent a few hours at the hardware store and made a replacement. Actually hear it build boost in neutral now.

Got the car to a car show this past weekend. Some general interest in what the car was. Ended up having to fill the empty coolant overfill bottle before leaving. Car stalled on startup/idle while leaving and tach seemed to only register half what the engine rpm was. Have yet to find out why it had such problems. Spark plugs, compression test, and visual inspections showed no symptoms.

Again from more experienced people, the piston rings are not sealing that well. Some blue smoke on overrun [aka::coming off boost] A very annoying thing seeing as, from what I've read on here, it was rebuilt with less than 200mi before I got it, and I rebuilt it to inspect for fire damage. This is why I did a visual inspection, cleaning, and didn't see the point in replace them. There's also a new noise, to me, that comes and goes form the turbo. Really hope I don't have to fix/repair everything again, really want to move onto suspension/tire upgrades.

Original Posted:: Wed Jun 22, 2016 7:58 pm

merkurdriver wrote:

What's inside that "PCV valve hardware store parts replacement" ?

I like to test my DIY stuff before posting something, good thing too since the O-ring didn't seal properly after a week and a half. All it has is a ball bearing and the O-ring sealed in place with sealant, with the three brass items visibly seen with plumbers tape. Just need to modify the larger 3/8" barb so air can get around the ball.

Anyways, replaced PCV with Motorcraft to eliminate it as a problem. Thought the oil catch can was spitting oil so I grocery bagged it before driving to see. Looks like the oil is coming from the dip stick. Car didn't have the plenum support bracket for the stick, but with the amount of oil spray I think it's more likely to be a head gasket issue.

Another problem, after sitting for a day the car does not want to idle right after starting. Have to throttle the car just to stop it from dying, after a minute it goes away. Getting worse. Also, tach has also comes and goes every once in a while, only reading a max 1100 rpm. Both issues might be caused by a TFI starting to fail, I need to find my spare to see.

Original Posted:: Tue Aug 09, 2016 1:54 pm

Found out a few weeks ago that the PCV valve needs to be mounted vertically to function right. Main reason I hate getting projects with someone elses work

Only good thing is no more serious oil loss problem now

The turbo has started to 'hum', I can only assume the engine bearings are in just as bad of shape. Will rebuild the turbo, for now, in hopes of taking it to Grattan Raceway VSCDA event for some Touring.

Original Posted:: Mon Aug 22, 2016 9:50 pm

As seen by the picture, the turbo bearings were charcoal [Left to Right: Replacement, Compressor, Turbine].

Surprisingly, the bores were not worn from original measurements =D

There's a rattling tin sound coming from around the turbo, like the turbo gasket hasn't seated properly. Will try to track it down.

Corner worked and toured at Grattan to feel out the car. Really enjoyed bringing the car to the event. Most everyone knows the car, and some even watched Hurst.

Light rain Saturday made the track a little oily, and with my lack of track experience, back end kicked out and put me in the ditch =P Managed to drive the car, properly, around the track Sunday. Tires are pretty much maxed out on grip and brake fade really started to show around the third lap. Pedal feel is a little spongy well afterwards, but I might just now be noticing it. Front lower control arm balls are a little loose just cruising around, can really notice under braking off the track straight.

Oil problem seems to have been fixed, however the dip stick still seems to be blowing off the tube. Also, throttling through the gears I can smell oil but never find any under the hood or smokey exhaust. Compression test didn't show any problems.

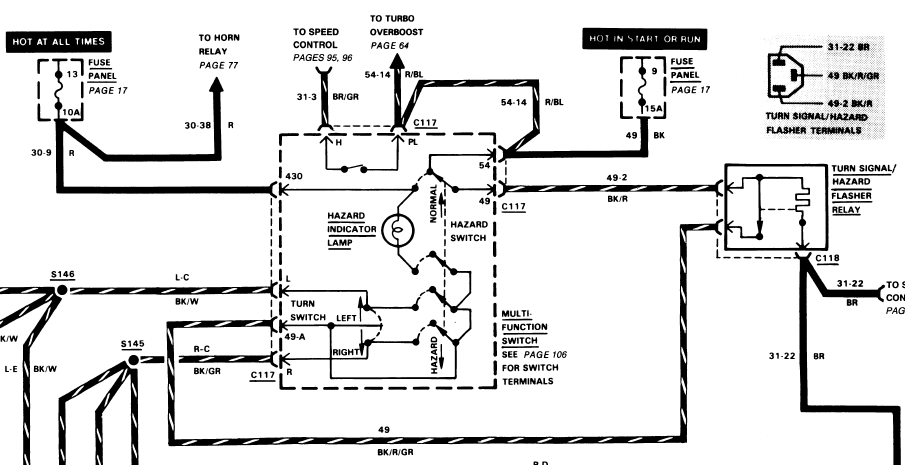

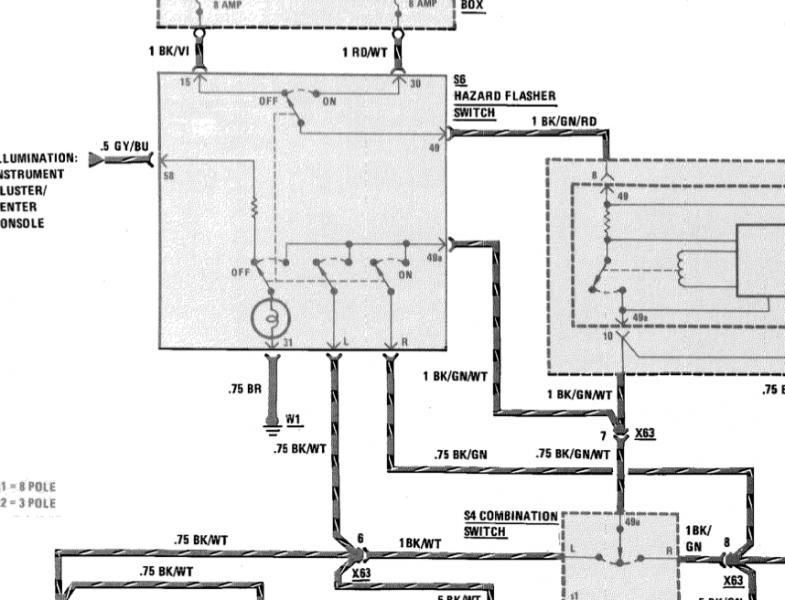

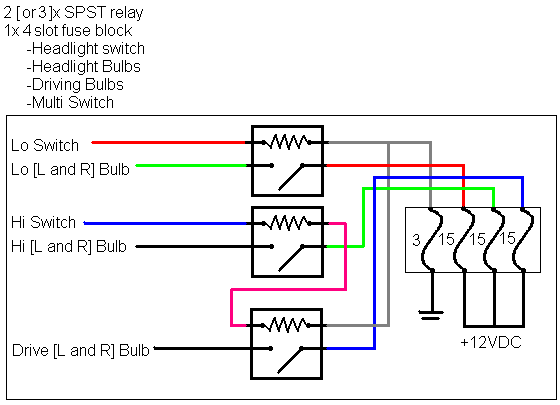

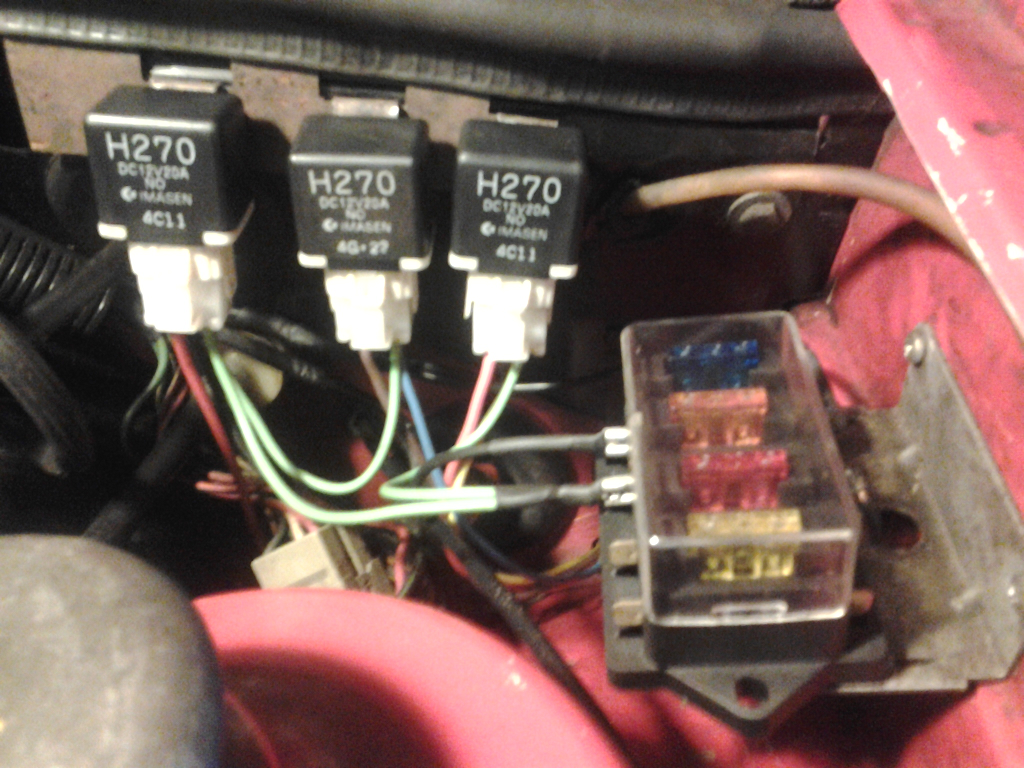

Upgrade/Mod list is still shaky, as well as getting a winter car. Really need to save for a T5 swap to finish mechanical/engine upgrades before getting into suspension, tires, and brakes. Electrical work is another issue to be addressed for future upgrades/swaps.

Original Posted:: Wed Aug 31, 2016 3:52 pm

Rattling at the turbo was the wastegate actuator linkage slightly over extended.

Going junkyard shopping. Bought a pair of '99 Mustang PBRs and rear Escape bracket adapters. The performance shelf is growing

Honestly considering buying the '99 brake master cylinder [1-1/16" bore] to try and put on the XR booster, looks like no adapter plate would be needed. Only thing I see as an issue is it's a little longer and the reservoir that comes with it will have to be used. Tapping the bleeder for a coupler will allow stock lines, for the most part, to be used.

Another design concept I'm working on is a full wishbone conversion, 70s mustang front and Cobra IRS rear layout. A lot of complications come up for the front, as well as the rear. There has been two ways that have been done for the front, goober in a mustang crossbrace or chop off the front and go tube frame. I am looking at another option, keeping lower control arm layout, swap to mustang ii knuckle and add upper arm, shock, and spring. Reinforce inner structure of body to support arm. This will leave the possibility to go back to OE. Sadly, my knowledge on the suspension mathematics has perished over the years. Hoping to pick it back up to see if the dynamics checks out before moving on. I don't have a CAD machine, nor a person to help me, so everything will be done old school, pencil, paper and a K-nex set =P

For the rear, I noticed the thread on here for the IRS swap. They have been too busy to make progress on the conversion. Another pioneering mission after the front.

I have a lot of ideas and controversial designs for this car. Money will always be a factor, so buying parts here and there will probably be the only progress this

project sees.