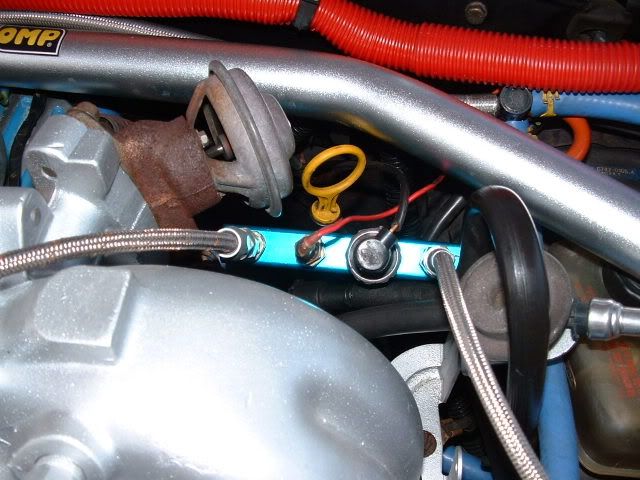

I was all ready to buy the SS lines from stinger, then I looked a little closer and found that the leak is only at threaded fitting the end of the line screws into. You know that 90 degree elbow that screws into the actual turbo housing, well oil bubbles up from that a little bit at idle and it must be significantly more under load.

I tried getting the oil line off from that elbow but I have the feeling its going to strip. I tried both cold and with the car heated up. It's almost like that elbow just needs to be tightened up a little more, it has a couple threads showing at the base.

Should I try to fix my stock oil line (it appears to be in very good shape) or should I just go right to a stainless steel replacement? And how hard is it to get to the back of the block and install the engine side of the feed line?

Is there a source for a new one of those little 90deg oil line elbows??

On a side note I started my internship (basically a full time job for 8 weeks) so the money is flowing in. I'm going to put it towards fixing the leak and upgrading power a little bit (3" dp and porting), and then hopefully redoing the entire suspension.